In 2019, D7 Pneumatics were contracted by Interfor's Eatonton Mill in Georgia to provide vital assistance with the upgrade of their planer mill.

Our experienced team was responsible for critical aspects, including underground utilities and fire protection for the new planer mill project and dry lumber sheds. Over an extended period, from September 2019 to January 2021, we successfully completed our role in the upgrade.

Interfor's Eatonton Division, a 39-acre site acquired from Rayonier in March 2013, is a crucial facility for turning cut and seasoned boards into finished dimensional lumber, shipping its finished products both by truck and rail, contributing significantly to Interfor’s lumber supply chain.

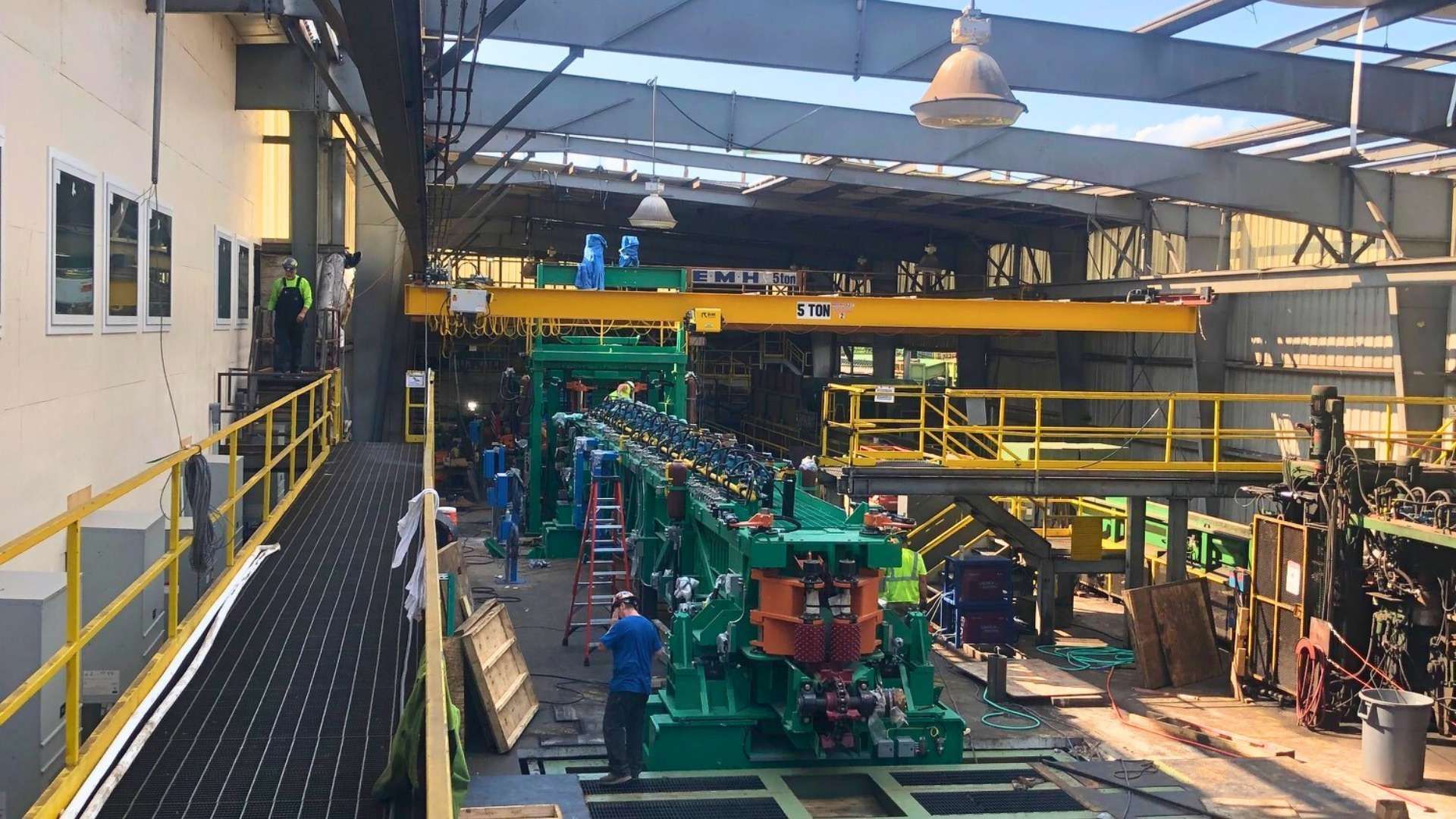

Our work on this project was part of a comprehensive rebuild of Interfor’s Eatonton Division - which was completed in 2022 - to align with their commitment to enhancing efficiency and operational capabilities. The rebuild's scope involved the overhaul of the planing mill, which houses various machines, including planers, matchers, molding machines, and a range of saws.

Interfor strives to stay at the forefront of industry advancements, and D7 Pneumatics' contribution to this project furthers our growing reputation as a trusted partner in facilitating the growth and development of key players in the lumber industry.

More Projects